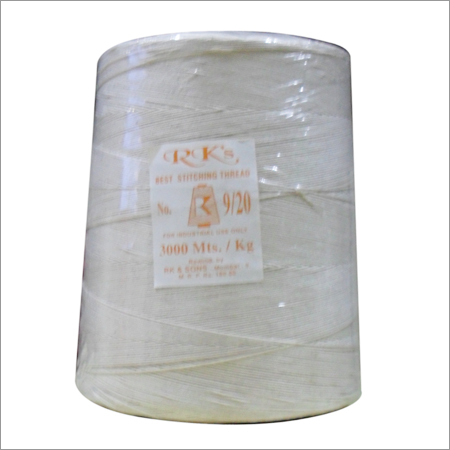

Polyproplyene Stitching Thread

Polyproplyene Stitching Thread Specification

- Twist direction

- S/Z twists available

- Length

- 1000m, 5000m or as required

- Material

- Polypropylene

- Properties

- Excellent chemical resistance, abrasion resistance, UV stabilized

- Style

- Continuous filament

- Usage

- Bag stitching, sack sewing, packaging industry

- Technique

- Twisted

- Yarn Type

- Filament

- Pattern

- Plain, solid

- Attributes

- Low elongation, knotless, smooth finish

- Weight

- Various options (commonly 200g, 500g cones)

- Yarn Count

- 210 Denier, 410 Denier (custom as required)

- Color

- White or customized

Polyproplyene Stitching Thread Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 8 Kilograms Tons Per Week

- Delivery Time

- 2-7 Days

About Polyproplyene Stitching Thread

Polyproplyene Stitching Thread:

With the support of our skilled professionals, we are offering our clients an exclusive range of Polypropylene Stitching Thread. The offered thread is processed at our sophisticated manufacturing unit using supreme class polypropylene keeping in mind latest market trends. Acknowledged for its long lasting shine, colorfastness, high strength, smooth texture and durability, this thread is widely demanded across the market. Available in 600 denier to 2500 denier, from 1000 meters to 5000 meters and 1kg to 3 Kg cones, clients can avail this Polypropylene Stitching Thread from us in different textures, colors and thicknesses at pocket friendly price.

Superior Durability and Chemical Resistance

Experience remarkable durability with our polypropylene stitching thread, built to withstand harsh chemicals, mechanical abrasion, and prolonged UV exposure. This makes it a trustworthy choice for demanding environments, maintaining integrity and strength even under rigorous use in the packaging industry.

Versatile Applications for Packaging Solutions

Our thread is meticulously engineered for versatile use across bag stitching, sack sewing, and a range of packaging solutions. Its low elongation, smooth surface, and knotless structure ensure high efficiency, reducing downtime and enhancing productivity for both manual and automated sewing systems.

FAQs of Polyproplyene Stitching Thread:

Q: How is polypropylene stitching thread used in the packaging industry?

A: Polypropylene stitching thread is commonly utilized for closing bags and sacks, as well as various other packaging tasks. Its durability and strength make it ideal for sewing heavy-duty materials in industries handling agricultural, chemical, and food products.Q: What are the main benefits of using this polypropylene stitching thread?

A: The primary advantages include excellent chemical and abrasion resistance, UV stabilization for outdoor use, and a smooth, knotless finish that facilitates easy sewing. Additionally, its low elongation ensures tight and secure stitches, making it reliable for long-term use.Q: When should I choose continuous filament yarn for stitching?

A: Continuous filament polypropylene yarn is preferred when high strength, minimal fuzz, and a consistent, smooth finish are required. It helps prevent thread breakage and is particularly suitable for applications where durability is crucial.Q: Where can I purchase this stitching thread?

A: This polypropylene stitching thread is available through authorized distributors, exporters, manufacturers, suppliers, and traders. You can request customization in color, length, and yarn count to fit your specific needs.Q: What is the manufacturing process for polypropylene stitching thread?

A: This thread is produced by extruding polypropylene into continuous filaments, which are then twisted to create a strong, uniform yarn. The thread undergoes rigorous quality checks to maintain consistency in properties and performance.Q: How do I select the correct thread weight and yarn count for my application?

A: Consider the material thickness and the required stitch strength for your project. Heavier weights and higher deniers (like 410 Denier) are suitable for thicker or heavier bags, while lighter options (such as 210 Denier) work well for smaller or lighter packaging. Customization is available to match your specific requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Textile Threads Category

Cotton Thread

Price Range 150.00 - 300.00 INR

Minimum Order Quantity : 50 Kilograms

Usage : Other, Garment Stitching, Embroidery, Quilting, Tailoring

Character : Other, Soft, Smooth Finish

Technique : Other, Ring Spun

Yarn Type : Other, Combed Cotton Thread

Polyester Bag Stitching Thread

Price Range 150.00 - 300.00 INR

Minimum Order Quantity : 50 Kilograms

Usage : Other, Bag stitching, packaging, sack closing

Character : Other, Strong and durable

Technique : Other, Spun and twisted

Yarn Type : Other, Filament polyester

Polyester Textured Threads

Price Range 150.00 - 300.00 INR

Minimum Order Quantity : 50 Kilograms

Usage : Other, Knitting, Weaving, Sewing, Embroidery

Character : Other, Textured

Technique : Other, Texturizing

Yarn Type : Filament

Overlock Threads

Price Range 150.00 - 300.00 INR

Minimum Order Quantity : 50 Kilograms

Usage : Other, Overlock Sewing, Garment Manufacturing

Character : Other, High Tensile Strength, Durable

Technique : Other, Spun with Advanced Machinery

Yarn Type : Filament

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS